Logistics

Production

Air freight

Air freight

Source: Lufthansa Systems AG

The availability of digital maps and GPS locating in combination with just-in-time production concepts or the auctioning of transport services has significantly increased the importance of

conventional route planning once again. This has diverse applications. Matheon develops innovative methods for planning truck routes and service vehicles as well as for controlling cargo ships,

freight trains and aircrafts or automated guided vehicles and elevators, the latter using innovative algorithms for modern destination call systems amongst others.

In evacuation planning, the selfish behavior of the persons involved as well as the time variation of the person flow play a key role. A new theory of dynamic flows allows for the first time

the analytic modeling, simulation and optimization of such non-cooperative scenarios.

Our particular strengths are super-fast route finding in networks, integrating localized routing and time scheduling decisions as well as optimizing the throughput of multistage transport

systems through to successfully solving major problems such as the control of container terminals and company-internal logistics systems.

Transport

Robot welding

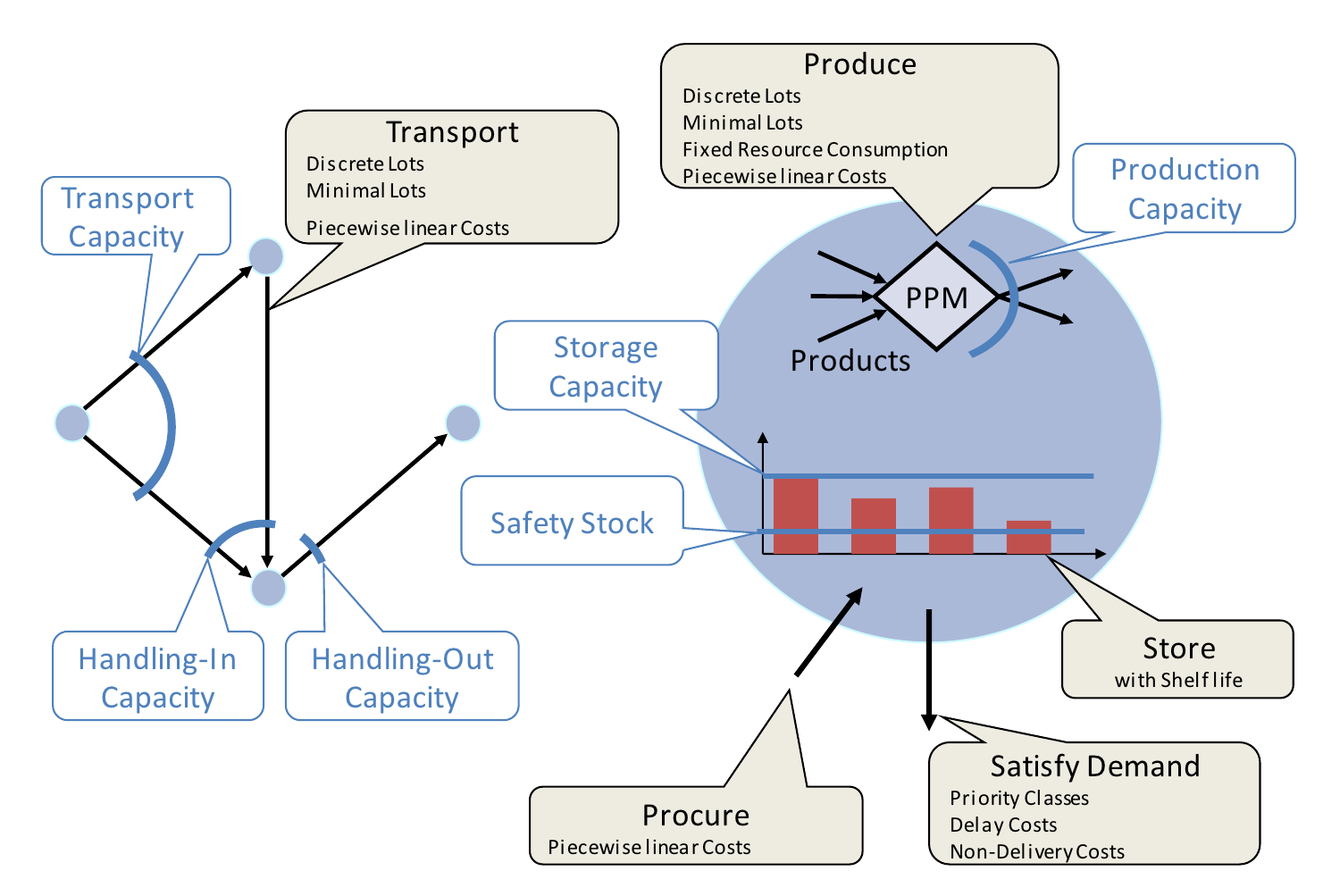

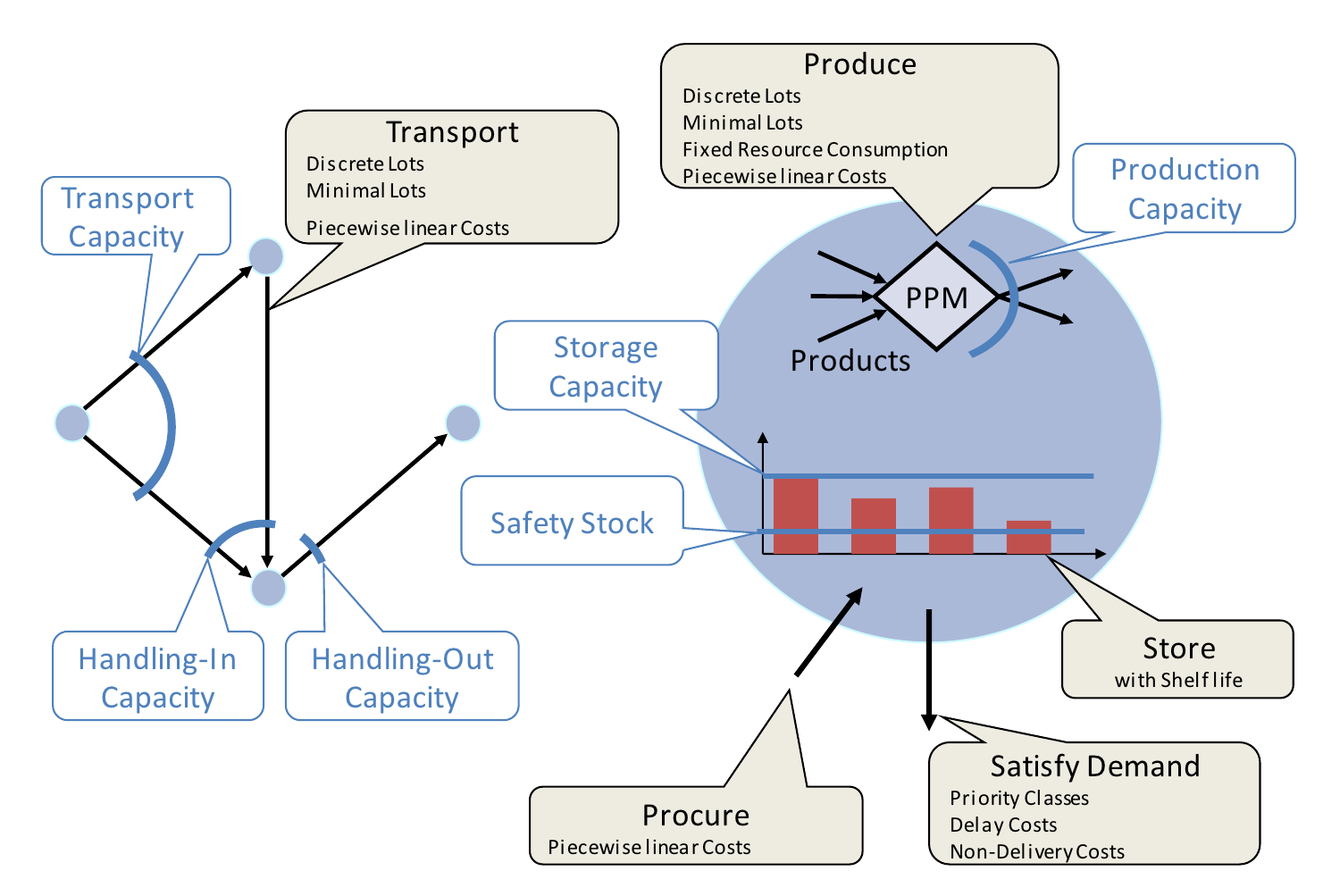

The combination of modern data logging technologies with intelligent forecasting, planning, control and monitoring methods forms the basis for efficient production logistics. From machine tool control and material flow optimization through to APS-assisted monitoring of process chains,

Matheon develops innovative solutions for time-relevant planning under complex production-related conditions. Depending on the application, we utilize methods of general linear, mixed-integer and constraint programming or special methods - above all from the network flow area.

Robot welding

The combination of modern data logging technologies with intelligent forecasting, planning, control and monitoring methods forms the basis for efficient production logistics. From machine tool control and material flow optimization through to APS-assisted monitoring of process chains,

Matheon develops innovative solutions for time-relevant planning under complex production-related conditions. Depending on the application, we utilize methods of general linear, mixed-integer and constraint programming or special methods - above all from the network flow area.

Matheon has extensive expertise in processing uncertain or incomplete data as well as in the development of methods with real-time capability. In the transition from deterministic to robust, stochastic or online models, Matheon applies new approximation methods with quality guarantees.

Operational Logistic

Automatic container transport in the Altenwerder terminal

Automatic container transport in the Altenwerder terminal

© HHLA – Hamburger Hafen und Logistik AG

The smooth functioning of company-internal logistic systems is crucial for efficient production. The optimization tasks here are diverse and require a broad spectrum of different techniques; they range from transport tasks (control of container terminals)

and sequence planning (production workflow in a steelworks) or flexible manufacturing (use of machine tools) through to complex time-sensitive control processes (production in the chemical industry).

Matheon therefore develops innovative methods of general non-linear mixed-integer optimization, with which modern advanced planning and scheduling (APS) systems can forecast capacities with the aim of controlling these optimally and time effectively etc.

At the same time, increasingly global cross-company cooperation makes production particularly prone to an escalating disparity in the material and goods flow (the so-called bullwhip effect).

Netzwork optimization

Cross-company process chain

The integrated planning of value added processes opens up improvement potentials that can be exploited using methods of linear and mixed integer optimization. In order to handle the very large,

detailed, structured and modular models involved in supply chain management (SCM), new decomposition methods must be developed. Matheon has a deep understanding of the entire solution technology from

modeling down to linear algebra, allowing it to master the numerical difficulties typical in the SCM area particularly well.

Cross-company process chain

The integrated planning of value added processes opens up improvement potentials that can be exploited using methods of linear and mixed integer optimization. In order to handle the very large,

detailed, structured and modular models involved in supply chain management (SCM), new decomposition methods must be developed. Matheon has a deep understanding of the entire solution technology from

modeling down to linear algebra, allowing it to master the numerical difficulties typical in the SCM area particularly well.

In future, logistics objects will be networked more closely by automatic identification and localization systems. The Internet of Things will improve the real-time responsiveness

of logistics centers through monitoring, event management and early warnings. Autonomous objects, agent-based control, independently controlled systems and intelligent load carriers will

control the systems in which they move ever more independently. The methods necessary for this must be developed in an interdisciplinary cooperation between logistics and IT specialists, engineers and mathematicians.

Matheon offers the competencies needed to realize such projects.

References

We have already implemented successful projects for various practice-relevant subjects with a range of prominent companies in the logistics sector and areas directly related. A selection can be found here:

- 4flow AG

- Alford Mining Systems

- DB Schenker Rail Deutschland AG

- Bundesamt für Güterverkehr

- ADAC

- Kollmorgen Steuerungstechnik GmbH

- Lufthansa Systems AG

- HHLA – Hamburger Hafen und Logistik AG

- Hermes Technischer Kundendienst

- Fiege eCom GmbH & Co. KG

- PSI Metals GmbH

- Sachsenmilch AG

- Salzgitter Flachstahl GmbH

- T. A. Cook & Partner Consultants GmbH

- VOLKSWAGEN AG

- WSV – Wasser- und Schifffahrtsverwaltung des Bundes

Our portfolio comprises the conduct of analyses, studies and consultancies, the development of models and algorithms, the computer-assisted simulation as well as the prototypical implementation of mathematical optimization methods. On request, we can convey spin-off companies for long-term software maintenance and updating.

Make the most of our expertise for a more efficient route to innovation!

Robot welding

Robot welding